One of the booming markets in the world today is the cosmetics market whereby millions of products are shipped in various regions on a daily basis. Strict packaging standards are vital to businesses to ensure safety, consistency, and trust to consumers. The inspection of cosmetics packaging is crucial to high quality where every product must not only appear stylish but also meet the quality and safety standards.

On examining the Asian market, China is a manufacturing giant in beauty and personal care products. The Chinese factories provide brands to different parts of the world because they are cheap and the production capacity is high. Nevertheless, in order to make these products be able to satisfy the international standards, companies are to focus on the quality control china processes. The key to that effort is the packaging inspection.

Why Packaging Inspection is Critical in the Cosmetics Industry

Packaging is not merely a pretty box or container, it is the initial level of product protection and the very first thing that is seen by the consumers. Substandard packaging may result in spoilt or broken goods, possibilities of contamination, and an unfavorable brand perception. Strong inspection controls the possible defects like inappropriate labeling, bad sealing, wrong materials, or bad printing.

In addition, as international markets become more regulated in the field of cosmetics, inspection is a sign that safety standards are adhered to with utmost strictness. As an example, packaging should frequently have precise lists of ingredients, expiration dates, and warning signs. Failure to do this important step may lead to brands being recalled, fined or losing their reputations in the long run.

Key Elements of Cosmetics Packaging Inspection

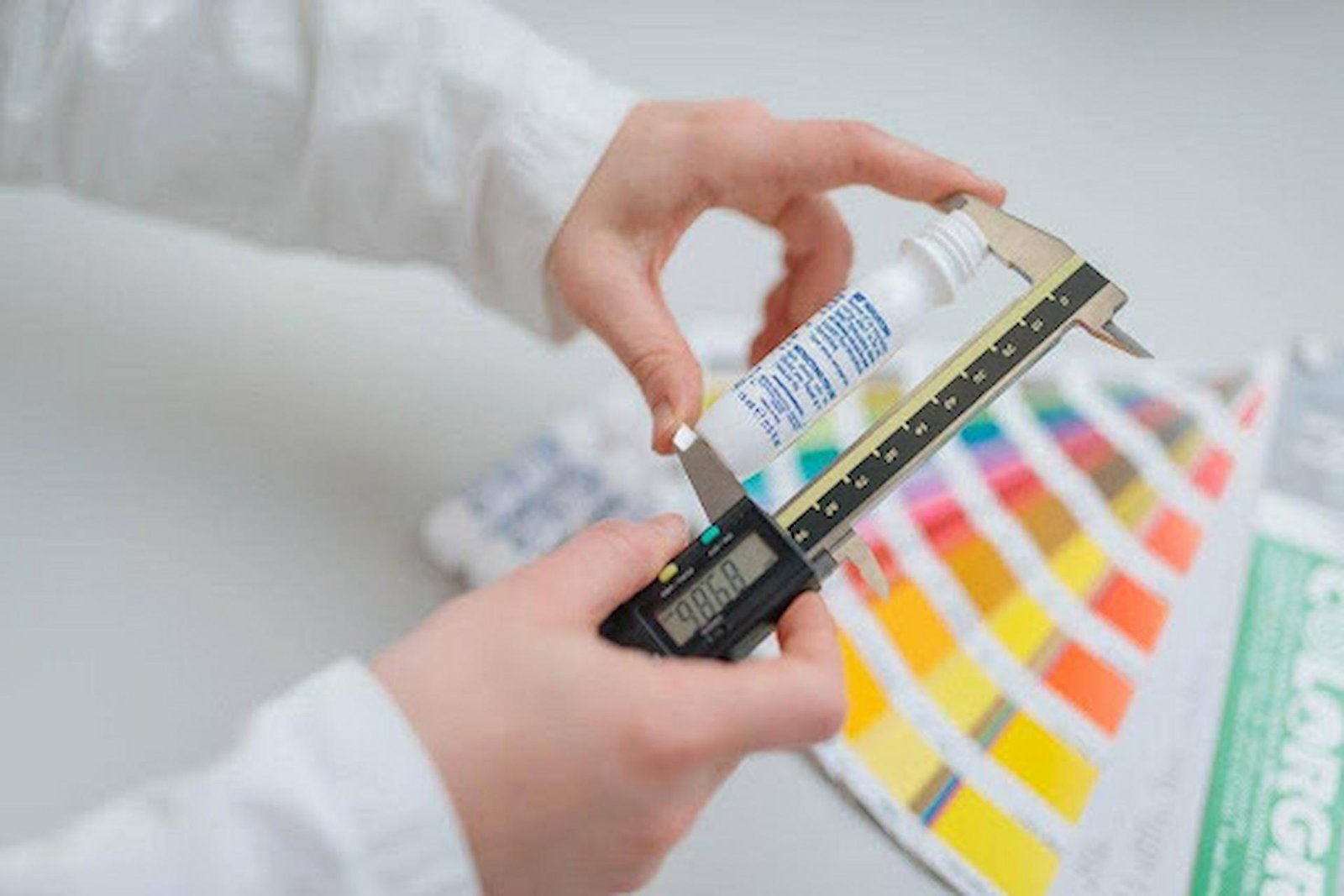

Packaging control includes the evaluation of several product features. Inspectors check on labeling accuracy, barcode readability, print quality and branding consistency. They also check on the durability of the materials used to ascertain that they can withstand the transportation and storage conditions.

Seal integrity and tamper-proof features are other important features and are essential to consumer safety. In the case of cosmetics such as creams, serums, and lipsticks, there is the leakage test as well as contamination prevention checks. Such attention to detail does not only safeguard the consumer, but also improves customer satisfaction as a whole.

The Role of Inspection in Maintaining Brand Trust

The beauty industry has its roots in trust. Consumers select brands that they feel are going to provide quality and safety on a regular basis. By ensuring that defective or non-conforming products are removed throughout the packaging process, the package inspection assists the companies in upholding that trust. The credibility of the brand can be affected by even minor mistakes in packaging, leading to the creation of negative reviews or bad social media attention.

Frequent check ups also give distributors and retail partners peace of mind. Suppliers who show a concern regarding the quality of packaging reinforce the relationships that they will have in the long term. To businesses that have to compete with others in heavily saturated markets, such an additional layer of security is a powerful selling point.

Quality Control in China’s Cosmetics Manufacturing

China has emerged as a powerhouse in the production of cosmetics in the luxury and affordable markets worldwide. As this expands, international purchasers have a tendency to depend on third party inspection organizations to monitor compliance. This is where quality control in China comes in so much importance. Manufacturers avoid risks and achieve uniformity of batches by integrating inspection in every place of production.

The inspection teams in China are localized, and they are trained to detect the faults in packaging and to check the adherence to both the regional and international standards. They assimilate foreign brands through cultural and regulatory disparities and this offers a sense of relief to enterprises that outsource their production. In the absence of these controls, businesses will face the threat of delayed shipments, regulatory disapproval, and customer dissatisfactions.

Challenges Faced in Cosmetics Packaging Inspection

Packaging inspection has its challenges despite its significance. A large problem here is the difference in the materials used since cosmetic products are usually specific in terms of containers such as airless pumps, glass jars or plastic tubes. Every material requires certain check-up procedures. As an example, glass containers should be checked with cracks, and plastic packaging should be tested in terms of durability and flexibility.

The other difficulty is the high volumes of production. Promotional lines or seasonal cosmetic products are also frequently introduced by companies, which strains the inspections teams. Due to a lack of adequate resources, quality checks can be hurried and thus overlooked. This renders it essential to companies collaborating with seasoned inspection providers that would be capable of handling the fluctuations in demand effectively.

Future Trends in Cosmetics Packaging Inspection

With sustainability emerging on the world agenda, there is increasing use of environmentally friendly packaging materials in the cosmetics sector. Nevertheless, new materials also demand special inspection procedures in order to make sure that they are durable and secure. As an example, biodegradable containers can be more susceptible to moisture damage and need more quality checks.

In addition, international regulatory controls are getting tougher particularly in terms of labeling accuracy and ingredient transparency. Brands will have to change by incorporating more effective inspection systems into their supply line. Individuals that adopt innovation and compliance will have a competitive advantage in the changing cosmetics environment.

Conclusion

The cosmetics sector is based on consumer confidence, safety of products and brand name. Cosmetics packaging inspection is one of the most critical processes in all quality assurance processes. The companies preserve their customers and build a significant position in the market by emphasizing the aspects of labeling, durability, and compliance. In the case of sourcing in Asia particularly in China, quality control china processes maintain products at international standards without compromising brand credibility.

Leave a Reply

You must be logged in to post a comment.